Reimagining Cargo Security with MEAP: Smart, Scalable, and Built for Tomorrow

In today’s global trade environment, the need for fast, accurate, and scalable cargo inspection systems has never been greater. Traditional single- or dual-energy X-ray solutions are increasingly limited by resolution constraints, material discrimination issues, and growing throughput demands. In response, LINEV Systems has developed a disruptive technology that sets a new industry benchmark: the Multi-Energy X-Ray Array Portal (MEAP).

Powered by Multi-Energy Array (MEA) technology, MEAP redefines how cargo and vehicle inspection is conducted by integrating synchronized high- and low-energy X-ray sources, real Dual-View geometry, and full-cycle AI processing in a scalable, modular design. The result is a screening system capable of delivering deeper penetration, sharper resolution, and real-time, automated threat recognition—even in the most demanding border, port, and customs environments.

What Makes MEA Technology Disruptive?

Unlike conventional systems that rely on a single or static dual-energy beam, MEA employs a distributed array of scanning modules, each tuned to distinct energy levels and geometries. These modules operate in parallel, generating multi-angle, multi-energy X-ray data. Through real-time fusion of this data, MEAP delivers:

- 2× better material discrimination (organic, inorganic, metallic)

- 2× higher spatial resolution for sharper threat detection

- 2× faster AI-powered throughput and decision-making

The ability to distinguish between substances such as drugs, explosives, plastics, and shielding materials is critical in modern inspection. MEAP’s multi-energy fusion approach gives AI more input data for recognizing unique material signatures. This enhanced material contrast drastically reduces false alarms and enables faster decisions, particularly in cluttered or mixed-content cargo.

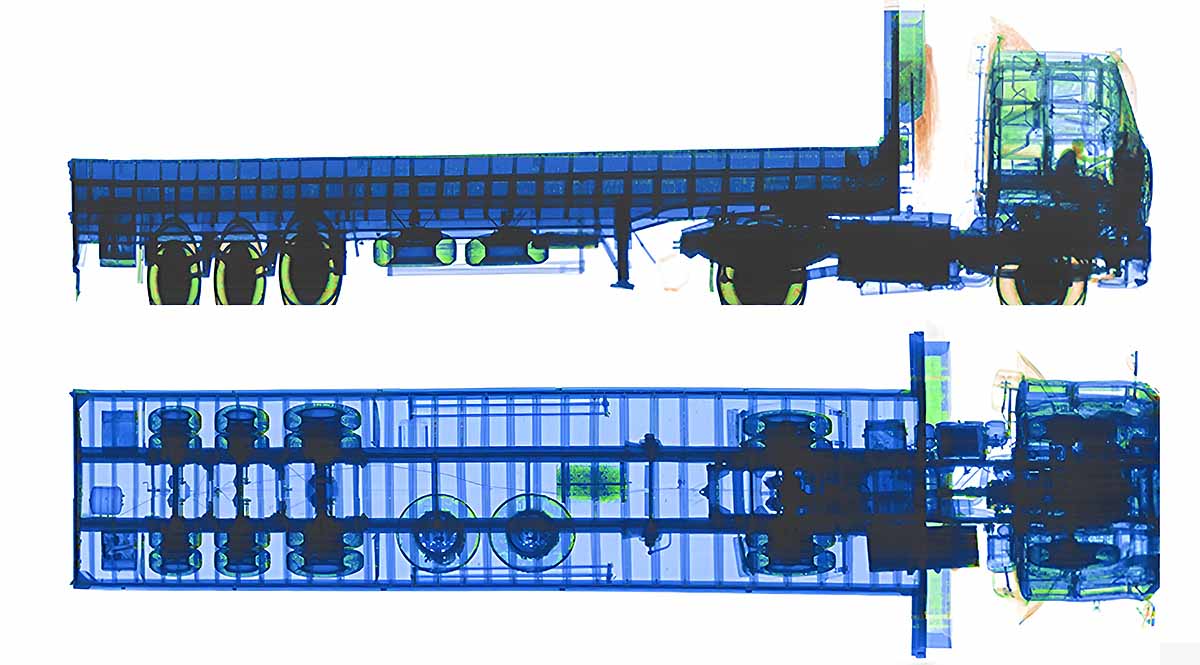

With vertical resolution down to 3 mm and horizontal resolution at 4 mm, MEAP detects smaller objects and hidden threats that traditional systems might miss. The spatial sharpness is critical for identifying concealed compartments, fine wiring, or shaped charges, especially when embedded inside dense or irregular shipments.

With vertical resolution down to 3 mm and horizontal resolution at 4 mm, MEAP detects smaller objects and hidden threats that traditional systems might miss. The spatial sharpness is critical for identifying concealed compartments, fine wiring, or shaped charges, especially when embedded inside dense or irregular shipments.

The MEAP Scanning Pipeline: From Penetration to Precision

- High-energy imaging delivers deep penetration to reveal concealed contents inside dense cargo. It is especially valuable for containers packed with steel, automotive parts, or electronics where lower energies are insufficient.

- Low-energy scanning improves contrast and spatial clarity, particularly for lightweight materials, void detection, and detailed analysis of the driver’s cabin or internal compartments.

- Dual-View geometry captures cargo from top and side angles in a single pass, eliminating blind zones and improving object separation for AI algorithms.

- Raw-level AI analysis ensures that fused, multi-energy, multi-view data is processed before the human operator sees it—supporting automated threat classification, anomaly alerts, and image prioritization.

This pipeline architecture ensures not only full data capture, but intelligent prioritization of operator attention—dramatically improving detection confidence and speed.

MEAP Image Quality Supermacy

Technical Capabilities at a Glance

- Steel penetration: up to 320 mm [12.6 in]

- Contrast resolution: 1% at 100 mm [3.9 in] steel

- Spatial resolution: 3.0 mm (vertical) [0.12 in], 4.0 mm (horizontal) [0.16 in]

- Throughput: up to 150 vehicles per hour

- Scanning speed: 5–15 km/h [3.1–9.3 mph]

- Imaging modes: Real-time, dual-energy fusion, full-color-coded material identification

- Operational temperature: -40 to +55 °C [-40 to +131 °F]

- Modular design: scalable from single-source to full Multi-Energy Dual-View configuration

Interview Insight: Rob Keeler on the Value of MEAPRob Keeler, Managing Director of LINEV Systems UK, emphasized how MEAP responds to challenges raised in collaboration with British border agencies and other international clients:

Speed and Congestion Relief – UK and EU entry points face pressure from rising cargo volume and reduced clearance resources. MEAP’s AI-first workflow significantly reduces inspection times and helps avoid trade bottlenecks by automating decision processes and eliminating unnecessary re-scans.

Complex Threat Environments – Across global markets, concealment tactics evolve faster than manual workflows can follow. MEAP’s full-spectrum scanning and raw-data AI detection deliver dependable results even in layered, shielded, or deceptive packaging—helping inspection teams stay ahead of increasingly sophisticated smugglers.

Readiness and Uptime – UK agencies in coastal and all-weather installations require 24/7 reliability. MEAP answers with robust climate protection (-40°C tested), automated system health diagnostics, and cloud-connected DMS support to detect anomalies before they lead to failure.

As Keeler states: “This is more than imaging. It’s a modular security platform with AI at its core—adaptable, scalable, and built for tomorrow’s threats.”

Modularity That Adapts to Your Needs

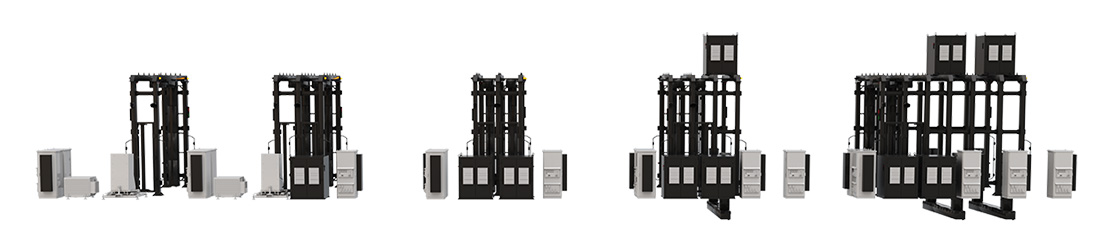

MEAP’s architecture is not one-size-fits-all. Customers can select a configuration based on actual inspection demands and available budget:

Single-view setups. Ideal for high-throughput, basic screening environments where top-side scanning is sufficient. A cost-effective entry point that can later be upgraded.

Dual-View expansions. Enhances depth analysis and object separation, particularly useful in detecting contraband hidden near structural vehicle elements or layered cargo.

Multi-Energy fusion add-ons. Enables advanced substance recognition and organic/inorganic differentiation—critical for narcotics, explosives, and illicit electronics.

Variaous MEAP Configrations

Beyond procurement flexibility, MEAP’s modularity simplifies lifecycle management:

Easier maintenance and part replacement. Swappable generator units, detector panels, and cabling allow on-site service with minimal downtime.

Interchangeable modules across networks. Customers operating multiple portals can reassign modules as operational needs shift or in the event of regional traffic surges.

Field upgrades without structural replacement. From power scaling to software licenses, MEAP supports performance growth without civil engineering or full redeployment.

For Whom and Where is MEAP Built?

MEAP is tailored for national border control, high-volume logistics terminals, customs clearance sites, and government-critical infrastructure.

| Application Area | Environment | Benefits | Cargo Types |

|---|---|---|---|

| Land Border Checkpoints | Drive-through, ground-level lanes | Reduces congestion with contactless scanning and high throughput (up to 150 vehicles/hour) | Passenger vans, buses, light and heavy trucks |

| Maritime Container Ports | Port-side fixed or gantry installations | Handles dense cargo, 24/7 use, resistant to corrosion and coastal climate | Standard containers, pallets, steel-cased shipments |

| Intermodal Terminals | Truck/train loading docks, logistics corridors | Integrates seamlessly with mixed transportation systems | Truck trailers, ISO containers, swap bodies |

| Strategic Air Cargo Facilities | Air freight zones and customs-controlled ULD areas | Scans oversized cargo and ULDs while meeting aviation security standards | Pallets, ULDs, consolidated freight |

From Vision to Real-World Deployment

MEAP systems are field-proven in both fixed and gantry-based installations, and support both LINAC and compact Linolac X-ray sources. Its modular nature supports phased implementation—from base portal to AI-enhanced, dual-angle, multi-energy powerhouses.

MEAP also integrates seamlessly into larger ecosystems. Its Digital Management Suite (DMS) enables:

- Remote monitoring and diagnostics

- Predictive failure alerts

- Cloud-based service analytics

- API integration with customs platforms and security networks

Live condition data is available for every component, enabling centralized oversight of regional deployments.

The system flags patterns that indicate wear or failure before they occur—reducing downtime and maximizing operational uptime.

Usage trends, performance benchmarks, and AI scoring rates can be visualized and analyzed from a secure central portal.

DMS supports easy data exchange with external databases (e.g. ANPR, ACCR, RPM, UVIS), enabling seamless coordination between hardware and software ecosystems.

The olnly technology to reveal smaller and dense objests simultaneously by Penetration + Resolution + Muti energy

Smart Screening for a Global Landscape

As post-Brexit trade shifts reshape infrastructure in the UK, and global customs authorities seek cost-efficient, high-performance solutions, MEAP stands out for its real-time automation, modular scale, and AI-native design.

For border operators, this means fewer false positives, reduced manual workload, and the power to preempt threats—not just respond. With MEA at its core, MEAP doesn’t just scan cargo—it transforms security inspection into a faster, smarter, and more resilient process.