Datasheet

As battery-powered devices proliferate, so does the complexity of recycling them. Portable batteries come in hundreds of formats, with varying chemistries and similar appearances. Traditional sorting methods—whether manual or optical—are no longer sufficient to keep up with regulatory demands, throughput pressure, and contamination risks.

Environmental compliance now requires more than visual identification. Toxic metals like cadmium and lithium can no longer be misclassified without consequence. Under EU Regulation 2023/1542, incorrect sorting of Ni-Cd batteries is subject to penalties, while mishandling lithium poses fire and reputational risks.

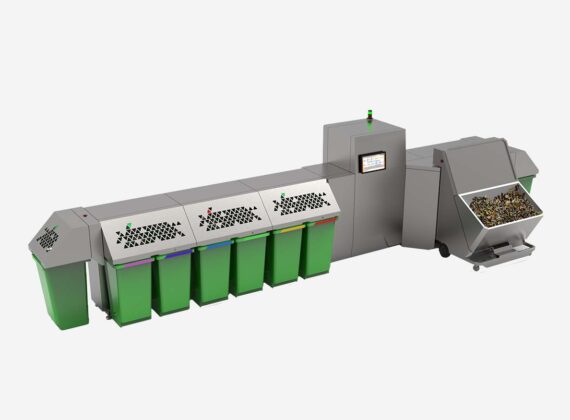

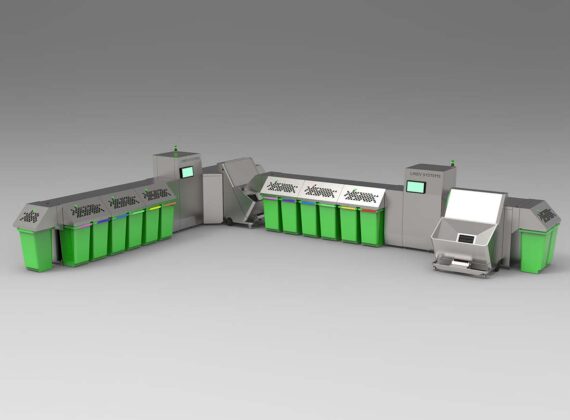

BATTERAY ZETA is our next-generation battery sorting solution, developed to go beyond the limitations of surface-based recognition. Using X-ray imaging and machine learning, it detects the internal structure of each battery—allowing precise classification by chemistry, regardless of label, shape, or condition.

To meet different operational needs, BATTERAY ZETA is offered in three scalable configurations:

| Platform | Sorting Capabilities | NiMH vs NiCd | Lithium-Ready |

|---|---|---|---|

| ZETA | Standard 6-group classification (Alk, Zn, Primary Li, NiCd/MH, Li-ion) | Grouped only (no separation) | Upgradeable |

| ZETA Gen1 | 6-group classification + NiCd vs NiMH separation | Yes (95%+ accuracy) | Upgradeable |

| ZETA Gen2 | Full classification + lithium detection (NMC, LFP, etc.) | Yes | Integrated |

All platforms are built for industrial deployment, enabling automated, high-throughput sorting with minimal operator intervention. ZETA helps recyclers boost yield, ensure compliance, and reduce reliance on visual inspection—even for damaged or unmarked cells.

The BATTERAY ZETA series introduces a two-tier platform tailored to evolving battery recycling needs. Generation 1 offers accelerated multi-chemistry sorting for facilities handling high-throughput alkaline and zinc-carbon streams, while Generation 2 includes dedicated NiCd/NiMH disaggregation—meeting strict regulatory guidelines like EU 2023/1542. Both share a compact form factor and are engineered for direct integration into existing battery handling workflows.

Each system level utilizes the same industrial-grade X-ray inspection hardware but is driven by distinct AI modules. With modular electronics and upgradeable software packages, ZETA adapts to different operational scenarios—from base-level sorting to advanced compliance-driven workflows with optional lithium-classification expansion via ZETA-Li.

- AI-driven battery sorting platform with patented X-ray analytics — classifies by internal structure, not external label or condition.

- Dedicated Ni-Cd and Ni-MH separation — ensures regulatory compliance and improves purity of downstream metal fractions.

- No visual cues required — ZETA detects battery chemistry even if labels are missing, damaged, or counterfeit.

- Lithium-classification ready — compatible with ZETA-Li for identifying NMC, LFP, NCA, and LCO cells.

Software Capabilities

- AI-enhanced classification using internal geometry, not surface features

- Configurable sorting profiles for expanded chemistry recognition

- Custom mode for rare or emerging battery types not on standard maps

Supported battery groups:

- Zinc–Carbon (ZnC)

- Alkaline (ALK)

- Nickel–Cadmium (NiCd)

- Nickel–Metal Hydride (NiMH)

- Mixed NiCd/NiMH group

- Lithium Primary (Li-SOCl₂, Li-MnO₂, Li-FeS₂) (optional)

- Lithium-Ion (NMC, LFP, LCO, NCA) (via ZETA-Li)

Classification Structure

Sort Map

| ZN | ALK | NiCd/MH | NiCd | NiMH | Primary Li | Li-Ion | |

| AAAA | + | + | + | + | + | ||

| AAA | + | + | + | + | + | + | + |

| AA | + | + | + | + | + | + | + |

| C | + | + | + | + | |||

| D | + | + | + | + | + | + | |

| 6F22 (9V) | + | + | + | + | |||

| 21700 | + | ||||||

| 18650 | + | ||||||

| A23 | + | ||||||

| A27 | + | ||||||

| CR2 | |||||||

| 16340 (R123) | + | + | |||||

| 1/2 AA | + |

Process Overview

After loading batteries into the system, they pass through a pre-screening conveyor that removes non-battery debris, metal fragments, dust, and undersized items. This filtration step protects internal mechanisms and improves sorting purity.

Next, the alignment stage orients batteries into a stable horizontal stream for scanning. Regardless of external markings or shape variations, the system ensures consistent positioning for accurate detection.

BATTERAY ZETA then scans each battery using a proprietary X-ray and visual sensor array. Deep-learning algorithms interpret the internal geometry and composition of every cell in real time—assigning it to a distinct group within the classification map.

Classified batteries are then sorted into dedicated output bins via pneumatic actuators. Unknown or ambiguous batteries are safely discharged into a fallback container for manual handling or database extension.

- Supports throughput up to 600 kg/h and over 18,000 batteries per hour.

- Delivers 99.5% purity for alkaline and zinc, over 95% for NiMH and NiCd groups.

- Expanded classification map includes mixed chemistries and optional lithium upgrade path.

Key features

AI-Driven Internal Classification

BATTERAY ZETA uses multi-sensor X-ray imaging and machine learning to classify batteries by internal geometry and density—without relying on external appearance or markings.

Ni-Cd & Ni-MH Separation

Generation 2 configuration enables independent sorting of Ni-Cd and Ni-MH batteries — a critical requirement for downstream purity and compliance with EU Regulation 2023/1542.

Lithium-Ready Architecture

BATTERAY ZETA supports lithium battery detection by default, and can be expanded to full lithium subgroup classification (NMC, LFP, LCO, NCA) via the ZETA-Li upgrade module.

Sorting Accuracy up to 99.5%

Delivers 99.5% purity for alkaline and zinc groups, and over 95% accuracy for lithium, NiMH, and NiCd — even when batteries are corroded, unmarked, or counterfeit.

Industrial Throughput with AI

Processes up to 18,000 batteries or 430 kg per hour. Self-optimizing software ensures continuous, efficient operation in large-scale, mixed-batch environments.

Modular, Patented Platform

BATTERAY ZETA is a scalable system with modular upgrades and software-driven sorting logic. Patented by LINEV Systems for unmatched safety and classification control.

Video

Technical data

X-ray source

| X-ray emission | Complies with the standard: 1 μSv/h at any point at a distance of 10 cm from the device. Typical value of our system less than 0.3 μSv |

| X-ray protection | Full operator protection |

Loading

| Loading hopper capacity, up to | 350 kg |

| Loading hopper volume | 250 L |

| Conveyor speed | 1.0 m/s |

| Productivity of pure fractions | up to 18000 batteries/hour |

| Pneumatic | 10 bar ±10%, ≥500 SLPM |

| Throughput capacity | 430 kg/hour |

Dimensions

| Overall dimensions (maximum) | ||

|---|---|---|

| Lenght | 8960mm | |

| Width | 2690 mm | |

| Height | 2400 mm |

| Layout | 15000 x 8000 mm |

|---|

| Weight (maximum) | 2500 kg |

|---|

Purity

| Zinc-carbon, alkaline | 99,5 % |

| All groups | >95 % |

X-ray source

| X-ray emission | Complies with the standard: 1 μSv/h at any point at a distance of 4 in from the device. Typical value of our system less than 0.3 μSv/h |

| X-ray protection | Full operator protection |

Loading

| Loading hopper capacity, up to | 772 lbs |

| Loading hopper volume | 66 gal (US) |

| Conveyor speed | 3.3 ft/s (≈7.4 mph) |

| Productivity of pure fractions | up to 18,000 batteries/hour |

| Pneumatic | 145 psi ±10%, ≥17.7 SCFM |

| Throughput capacity | 948 lbs/hour |

Dimensions

| Overall dimensions (maximum) | ||

|---|---|---|

| Length | 29 ft 5 in | |

| Width | 8 ft 10 in | |

| Height | 7 ft 10 in |

| Layout | 49 ft 3 in × 26 ft 3 in |

|---|

| Weight (maximum) | 5,512 lbs |

|---|

Purity

| Zinc-carbon, alkaline | 99.5 % |

| All groups | >95 % |

Reviews and related links

Recycling facilities face growing pressure to handle increasingly complex battery waste — from mislabeled cells to fire-prone lithium types and tightly regulated nickel chemistries. Conventional methods fail to deliver the precision or scalability required for today’s waste streams.

BATTERAY ZETA™ offers a new technological foundation for safe, automated sorting. Its advanced platform supports internal structural analysis, AI-powered classification, and modular scaling to meet both current and emerging recycling demands — including the separation of Ni-Cd and Ni-MH, and lithium battery subtype detection.

Built on years of industry experience and powered by patented X-ray technologies, BATTERAY ZETA™ is more than an upgrade — it’s a strategic step into the future of battery recycling.

The fastest way to hear back from us is to fill the contact form below. Our appropriate department will get back to you depending on your inquiry as soon as possible.