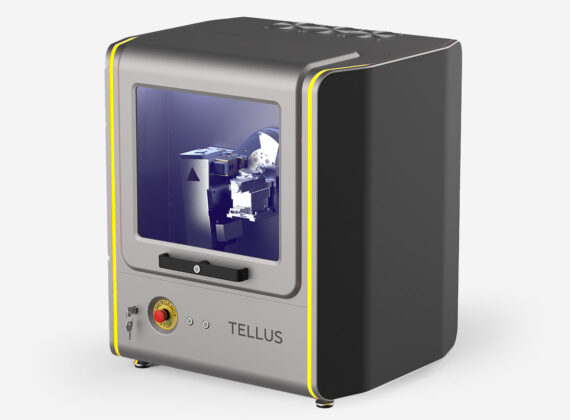

TELLUS Pro – Description

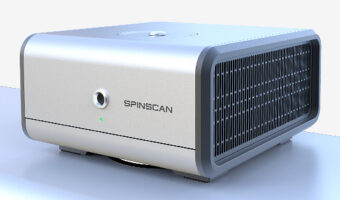

TELLUS PRO is the next-generation benchtop X-ray diffractometer, designed with enhanced capabilities and advanced functionality that empower researchers to perform a wide range of experiments with unparalleled versatility.

This high-tech instrument meets the demanding requirements of modern materials science, chemistry, and physics, offering both precision and flexibility for scientific research and high-tech manufacturing.

In contrast to the entry-level TELLUS BASIC, which is best suited for education and routine powder analysis,

TELLUS PRO is engineered for academic research and advanced industrial tasks. It supports not only standard powder diffraction but also complex measurements such as:

- Grazing Incidence X-ray Diffraction (GIXRD)

- Residual stress and texture analysis

- X-ray Reflectometry (XRR)

- Thin-film characterization

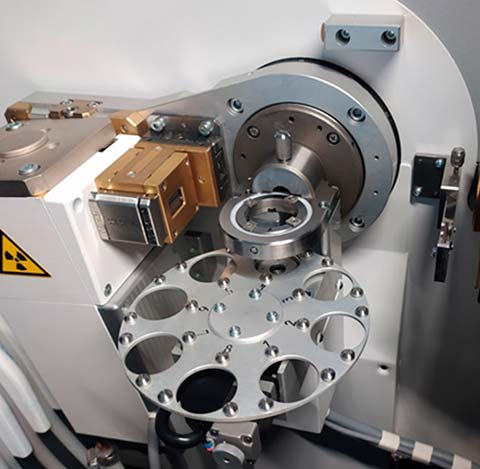

The system is equipped with a high-precision goniometer with uncoupled arms, enabling both symmetric and asymmetric scans,

and includes a 2-axis sample stage for accurate positioning. Combined with quasi-parallel beam optics (Goebel mirrors and parallel plate collimators),

TELLUS PRO offers flexibility and reliability in demanding applications, including microelectronics, coatings, and multilayer structures.

Thanks to its extended angular range and customizable software platform, TELLUS PRO allows researchers to explore material structures in greater depth and with higher confidence.

Whether used in academic laboratories or in high-tech industrial R&D, it provides the tools required for data-rich, reproducible experiments — without the complexity or footprint of a floor-standing diffractometer.

Comparison with other TELLUS models

| Feature / Model | TELLUS BASIC | TELLUS PRO | TELLUS INDUSTRY | TELLUS HR |

|---|---|---|---|---|

| Target Audience | Education, research, routine QC labs | Research, high-tech industry | Cement, mining, metallurgy, process control | Advanced R&D, semiconductor, epitaxy |

| Goniometer Radius | 150 mm | Variable, 150–210 mm | 150 mm fixed industrial mount | High-precision 240 mm |

| Scanning Range (2Ө) | –6° to +154° | –12° to +160° | –6° to +154° | –20° to +170° |

| Thin-Film Analysis | Limited | GIXRD, XRR, texture analysis | Not required | HRXRD, RSM, XRR, epitaxial film analysis |

| Residual Stress & Texture | Not available | Available | Not required | High-resolution residual stress & texture mapping |

| Sample Stage | Fixed with optional rotation | Two-axis Z-Phi stage | Automated loading carousel or batch tray | Five-axis motorized goniometer stage |

| Accessories | Basic powder holders | Goebel mirror, parallel plate collimator, capillary stage | Integrated autosampler, dust-protected chassis, LIMS-ready interface | High-res optics, beam conditioners, advanced sample environment |

| X-ray Generator | 40 kV / 15 mA (600 W) | 40 kV / 30 mA (1200 W) | 40 kV / 15–30 mA (up to 1200 W) | High-stability 3 kW system (optional) |

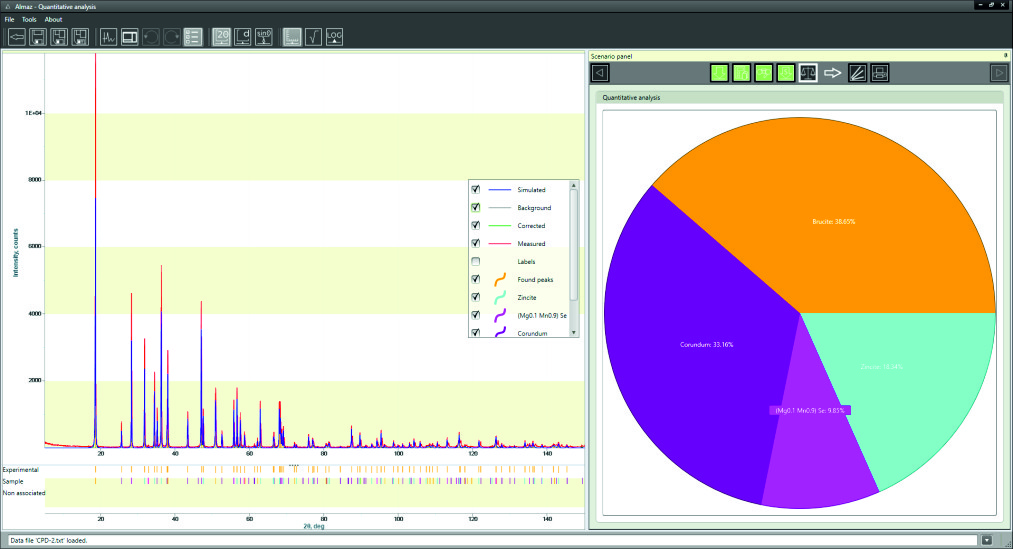

Software package

- TELLUSCon

- Specialized Software

- COD, PDF-2 databases

Key Applications:

- Crystal structure determination, including lattice parameters

- Phase analysis in multicomponent samples

- Texture analysis

- Residual stress evaluation

- X-ray reflectometry (XRR)

- Grazing incidence XRD (GIXRD)

- Temperature-dependent XRD measurements

Key features

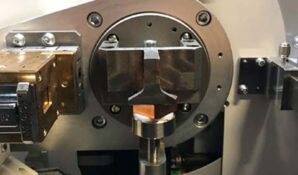

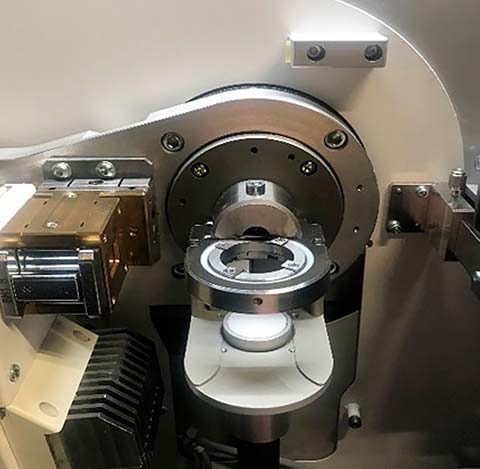

Uncoupled goniometer

High-precision goniometer with independently driven arms enables both symmetric and asymmetric scan geometries for advanced measurement flexibility.

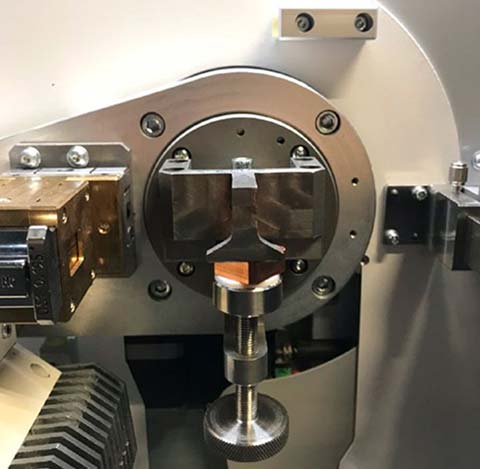

Dual-axis sample stage

Motorized sample holder with two axes of rotation provides precise positioning and alignment, ideal for thin-film and residual stress measurements.

Parallel-beam optics

Goebel mirrors and parallel plate collimators enable high-quality data acquisition in grazing incidence, reflectometry, and texture analysis.

Extended angular range

Broad 2Ө scanning range supports both low-angle and high-angle measurements, ensuring full coverage for advanced material investigations.

No external cooling

Efficient thermal management eliminates the need for external cooling systems, simplifying installation and reducing maintenance costs.

Advanced measurement modes

Supports specialized techniques including grazing incidence (GIXRD), reflectometry (XRR), residual stress, and texture analysis.

Video

Technical data

Details

| X-ray generator | 40 kV / 30 mA (1200 W) or 40 kV / 15 mA (600 W) |

| Target | Cu (optional: Cr, Co, Fe, Mo) |

| Cooling system | Internal water cooling (closed-circuit) |

| Goniometer | Vertical Ө–Ө, uncoupled, radius 150–210 mm |

| Scanning range (2Ө) | –12° to +160° |

| Source angle range | –6° to +125° |

| Detector angle range | –6° to +145° |

| Minimal step (2Ө) | 0.0003° |

| Positioning accuracy | ±0.01° (2Ө) |

| Scanning speed | 0.01–600°/min |

| Min. achievable FWHM | ≤0.03° |

Peripherals

| Detector | Photon-counting Si: ADVACAM MiniPIX TPX3 (2D) or DECTRIS MYTHEN2 R (1D) |

| Interface | USB / Ethernet |

| Computer | PC with Windows OS |

Dimensions

| Overall dimensions | |

|---|---|

| Width | 700 mm |

| Depth | 700 mm |

| Height | 860 mm |

| Weight (maximum) | 115 kg |

|---|

Details

| X-ray generator | 40 kV / 30 mA (1200 W) or 40 kV / 15 mA (600 W) |

| Target | Cu (optional: Cr, Co, Fe, Mo) |

| Cooling system | Internal water cooling (closed-circuit) |

| Goniometer | Vertical Ө–Ө, uncoupled, radius 5.91–8.27 in |

| Scanning range (2Ө) | –12° to +160° |

| Source angle range | –6° to +125° |

| Detector angle range | –6° to +145° |

| Minimal step (2Ө) | 0.0003° |

| Positioning accuracy | ±0.01° (2Ө) |

| Scanning speed | 0.01–600°/min |

| Min. achievable FWHM | ≤0.03° |

Peripherals

| Detector | Photon-counting Si: ADVACAM MiniPIX TPX3 (2D) or DECTRIS MYTHEN2 R (1D) |

| Interface | USB / Ethernet |

| Computer | PC with Windows OS |

Dimensions

| Overall dimensions | |

|---|---|

| Width | 27.6 in |

| Depth | 27.6 in |

| Height | 33.9 in |

| Weight (maximum) | 254 lb |

|---|

Related links

The fastest way to hear back from us is to fill the contact form below. Our appropriate department will get back to you depending on your inquiry as soon as possible.