TELLUS Industry – Description

TELLUS Industry is a dedicated benchtop X-ray diffractometer built for continuous, unattended powder analysis in industrial settings. It delivers rapid, accurate results around the clock, supporting high-throughput environments such as cement plants, mining sites, and materials production facilities.

Designed for seamless integration into automated workflows, it supports up to 800 samples per day and connects easily with LIMS or MES systems. With industrial-grade durability, built-in autosampling, and targeted application modules for cement and raw materials, TELLUS Industry ensures consistent quality control from raw mix to final product.

Unlike standard benchtop XRD systems, TELLUS Industry is optimized for large-scale, repetitive sample testing in industrial workflows. It is particularly effective for high-frequency phase and compound analysis in:

- Clinker phase quantification (alite, belite, aluminate, ferrite)

- Raw meal and cement composition monitoring

- SCM analysis (slag, fly ash, pozzolans, calcined clays)

- Hydration state evaluation and strength development

- Quality control of mining and metallurgical powders

- Automated inline or near-line LIMS-driven sampling

TELLUS Industry is engineered to meet the high-volume, real-world demands of industrial powder X-ray diffraction. Whether installed in a cement plant laboratory, a mining QC center, or a large-scale materials processing facility, it provides robust, reproducible results with minimal operator involvement. Its internal automation supports up to 800 samples per day, dramatically reducing manual labor and turnaround time.

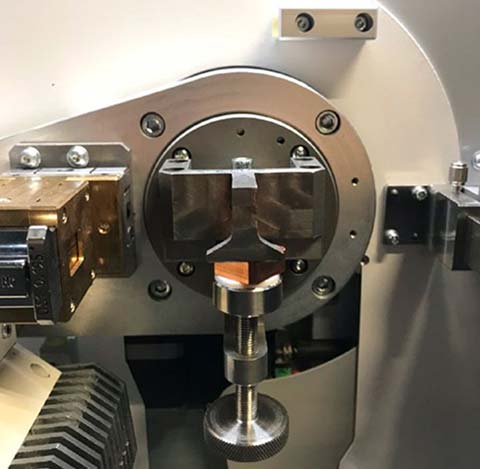

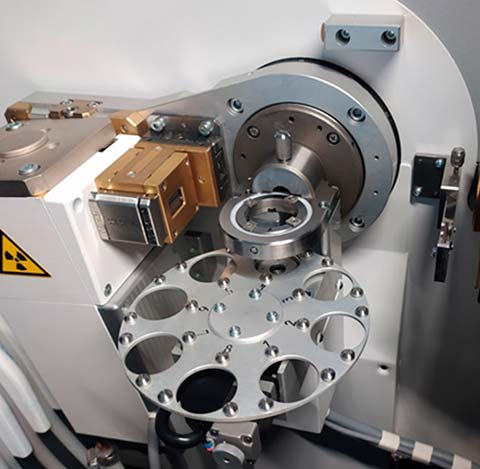

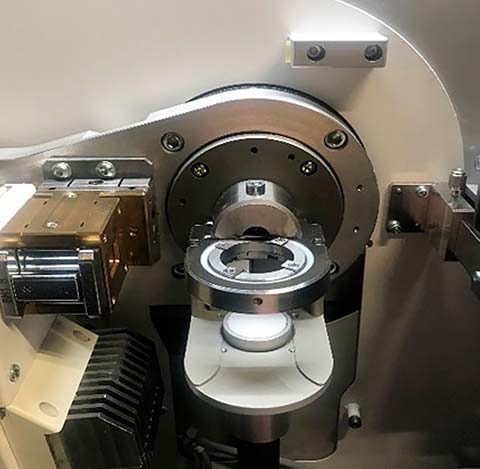

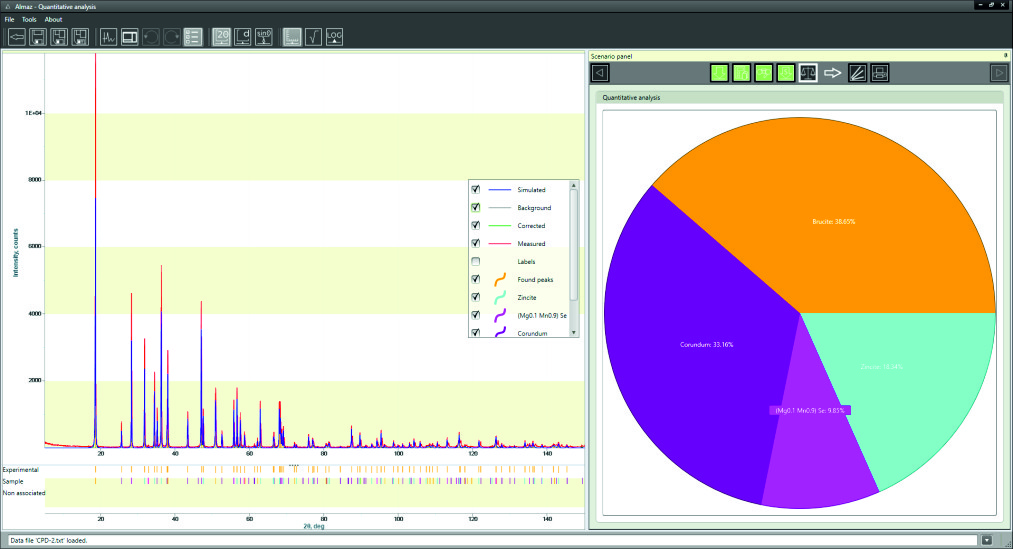

Unlike general-purpose diffractometers, TELLUS Industry offers targeted capabilities developed specifically for the analysis of complex industrial mixtures. Its precision-engineered goniometer, rapid scan rates (up to 600°/min), and durable X-ray source ensure long-term, maintenance-free operation under heavy workloads. Smart autosampler integration allows batch-mode analysis and continuous feed operation to match demanding production cycles.

Specialized application modules and customizable measurement protocols make TELLUS Industry especially powerful for cement analytics — including quantitative phase analysis, free lime control, hydration state evaluation, and supplementary cementitious material (SCM) characterization. Whether analyzing raw meal, clinker, or final cement products, the system delivers precise mineralogical data essential for process optimization and regulatory compliance.

TELLUS Industry can be seamlessly connected to LIMS, SCADA, or MES systems, enabling real-time data logging and automated quality assurance across the production chain. Combined with its small footprint and rugged construction, the system is ideal for near-line or in-line integration in industrial environments, providing a future-ready solution for modern materials manufacturing.

Comparison with other TELLUS models

| Feature / Model | TELLUS BASIC | TELLUS PRO | TELLUS INDUSTRY | TELLUS HR |

|---|---|---|---|---|

| Target Audience | Education, research, routine QC labs | Research, high-tech industry | Cement, mining, metallurgy, process control | Advanced R&D, semiconductor, epitaxy |

| Goniometer Radius | 150 mm | Variable, 150–210 mm | 150 mm fixed industrial mount | High-precision 240 mm |

| Scanning Range (2Ө) | –6° to +154° | –12° to +160° | –6° to +154° | –20° to +170° |

| Thin-Film Analysis | Limited | GIXRD, XRR, texture analysis | Not required | HRXRD, RSM, XRR, epitaxial film analysis |

| Residual Stress & Texture | Not available | Available | Not required | High-resolution residual stress & texture mapping |

| Sample Stage | Fixed with optional rotation | Two-axis Z-Phi stage | Automated loading carousel or batch tray | Five-axis motorized goniometer stage |

| Accessories | Basic powder holders | Goebel mirror, parallel plate collimator, capillary stage | Integrated autosampler, dust-protected chassis, LIMS-ready interface | High-res optics, beam conditioners, advanced sample environment |

| X-ray Generator | 40 kV / 15 mA (600 W) | 40 kV / 30 mA (1200 W) | 40 kV / 15–30 mA (up to 1200 W) | High-stability 3 kW system (optional) |

Software package

- TELLUSCon

- Specialized Software

- COD, PDF-2 databases

Key Applications:

- Crystal structure determination (including lattice parameter refinement)

- Multicomponent phase analysis

- Texture analysis

- Residual stress evaluation

- X-ray reflectometry (XRR)

- Grazing incidence XRD (GIXRD)

- Small-angle X-ray scattering (SAXS)

- Temperature-dependent XRD

Key features

Industrial-grade automation

Designed for unattended 24/7 operation with integrated autosampler, automatic processing, and continuous quality control.

High throughput capacity

Analyzes up to 800 samples per day with batch processing for raw meal, clinker, SCMs, and cement.

Specialized for cement and mining

Optimized for phase quantification, free lime control, and SCM evaluation in cement and raw material processing.

LIMS-ready integration

Seamless connection with LIMS, SCADA, or MES systems for automated data handling and centralized quality reporting.

Compact, rugged design

Industrial chassis with dust protection and compact footprint ensures long-term reliability in production environments.

Maintenance-free operation

Internal water cooling, sealed mechanics, and robust hardware ensure minimal maintenance and high uptime.

Video

Technical data

Details

| Tube power | 600–1200 W |

| Target | Cu (others optional) |

| Cooling system | Internal water cooling: closed-circuit |

| Goniometer | Ө–Ө vertical, industrial-grade, 150 mm |

| Scanning range | –6° to +154° (2Ө) |

| Minimal step | 0.0003° (2Ө) |

| Positioning accuracy | ±0.01° (2Ө) |

| Scanning speed | 0.01–600°/min |

Peripherals

| Interface | USB / Ethernet / LIMS-ready |

| PC & Software | PC with Windows, Industry XRD Suite |

Dimensions

| Overall dimensions | |

|---|---|

| Width | 700 mm |

| Depth | 750 mm |

| Height | 900 mm |

| Weight (maximum) | 120 kg |

|---|

Details

| Tube power | 600–1200 W |

| Target | Cu (others optional) |

| Cooling system | Internal water cooling: closed-circuit |

| Goniometer | Ө–Ө vertical, industrial-grade, 5.9 in |

| Scanning range | –6° to +154° (2Ө) |

| Minimal step | 0.0003° (2Ө) |

| Positioning accuracy | ±0.01° (2Ө) |

| Scanning speed | 0.01–600°/min |

Peripherals

| Interface | USB / Ethernet / LIMS-ready |

| PC & Software | PC with Windows, Industry XRD Suite |

Dimensions

| Overall dimensions | |

|---|---|

| Width | 27.6 in |

| Depth | 29.5 in |

| Height | 35.4 in |

| Weight (maximum) | 265 lbs |

|---|

Related links

The fastest way to hear back from us is to fill the contact form below. Our appropriate department will get back to you depending on your inquiry as soon as possible.