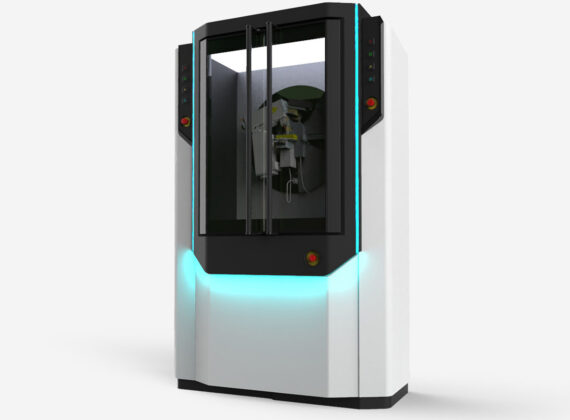

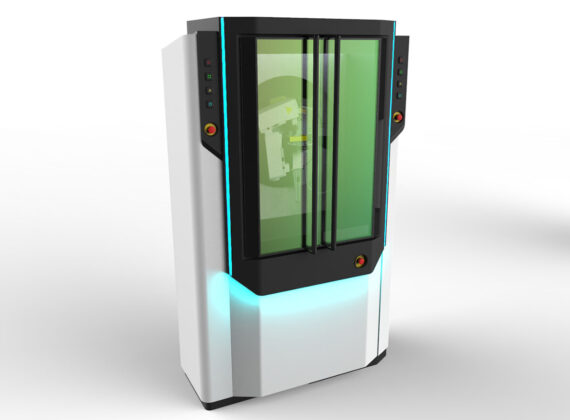

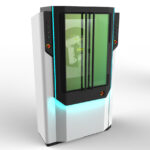

TELLUS HR – Description

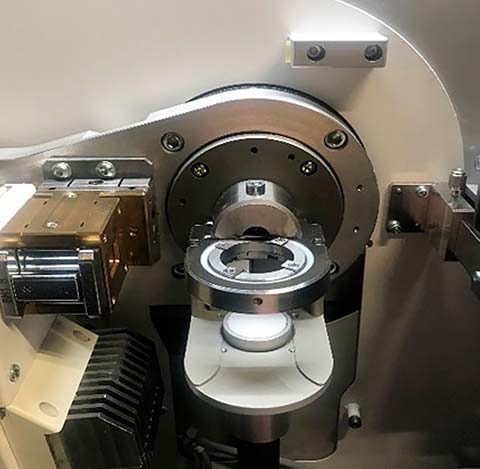

TELLUS HR is a high-resolution X-ray diffractometer designed for demanding research in structural crystallography, epitaxial layers, and advanced thin films.

With laboratory-grade stability, a configurable optical system, and a variable-radius goniometer, it delivers exceptional angular resolution for precise phase analysis, stress evaluation, and texture studies in cutting-edge materials science and semiconductor R&D.

While TELLUS BASIC and PRO cover routine analysis and advanced research respectively, TELLUS HR is tailored for high-resolution tasks that require maximum angular precision and structural sensitivity. It expands XRD capabilities into the realm of cutting-edge applications, including:

- Epitaxial thin-film analysis and reciprocal space mapping (RSM)

- High-resolution residual stress and texture studies

- Phase transitions and structural refinement

- Ultra-narrow peak detection (FWHM ≤ 0.01°)

TELLUS HR is engineered to meet the most rigorous demands of high-resolution X-ray diffraction. It delivers superior angular precision, sensitivity, and system stability — making it an ideal choice for laboratories working on epitaxial layers, functional coatings, and advanced material systems.

Its variable-radius Ө–Ө goniometer (150–310 mm), uncoupled scan geometry, and modular optics enable researchers to explore complex structures with unprecedented resolution. Whether analyzing thin films, residual stress, or microstructural evolution, TELLUS HR provides the analytical depth and flexibility needed for state-of-the-art experiments.

Applications include semiconductor epitaxy, functional coatings, nanomaterials, pharmaceuticals, and precision structural studies in academic and industrial R&D settings.

Compared to other models in the TELLUS Series, HR offers the highest level of configurability and measurement accuracy. Its advanced detector options, high-powered X-ray source (up to 3 kW), and support for 1D/2D acquisition modes position it as the ultimate XRD platform within the benchtop class.

Intuitive software, robust construction, and flexible integration with a wide range of accessories make TELLUS HR a long-term investment in scientific precision and reliability.

Comparison with other TELLUS models

| Feature / Model | TELLUS BASIC | TELLUS PRO | TELLUS INDUSTRY | TELLUS HR |

|---|---|---|---|---|

| Target Audience | Education, research, routine QC labs | Research, high-tech industry | Cement, mining, metallurgy, process control | Advanced R&D, semiconductor, epitaxy |

| Goniometer Radius | 150 mm | Variable, 150–210 mm | 150 mm fixed industrial mount | High-precision 240 mm |

| Scanning Range (2Ө) | –6° to +154° | –12° to +160° | –6° to +154° | –20° to +170° |

| Thin-Film Analysis | Limited | GIXRD, XRR, texture analysis | Not required | HRXRD, RSM, XRR, epitaxial film analysis |

| Residual Stress & Texture | Not available | Available | Not required | High-resolution residual stress & texture mapping |

| Sample Stage | Fixed with optional rotation | Two-axis Z-Phi stage | Automated loading carousel or batch tray | Five-axis motorized goniometer stage |

| Accessories | Basic powder holders | Goebel mirror, parallel plate collimator, capillary stage | Integrated autosampler, dust-protected chassis, LIMS-ready interface | High-res optics, beam conditioners, advanced sample environment |

| X-ray Generator | 40 kV / 15 mA (600 W) | 40 kV / 30 mA (1200 W) | 40 kV / 15–30 mA (up to 1200 W) | High-stability 3 kW system (optional) |

Software package

- TELLUSCon

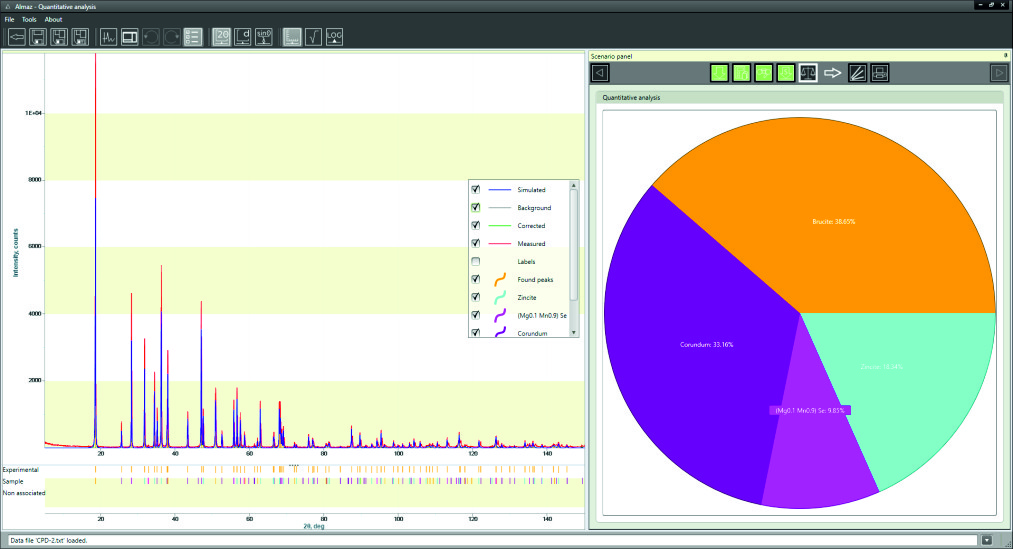

- Specialized Software

- COD, PDF-2 databases

Key Applications:

- Crystal structure determination (including lattice parameter refinement)

- Multicomponent phase analysis

- Texture analysis

- Residual stress evaluation

- X-ray reflectometry (XRR)

- Grazing incidence XRD (GIXRD)

- Small-angle X-ray scattering (SAXS)

- Temperature-dependent XRD

Key features

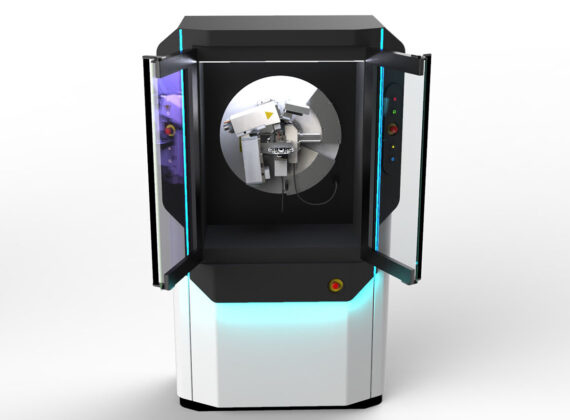

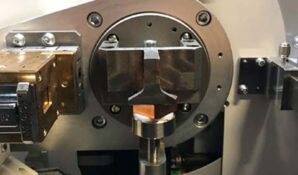

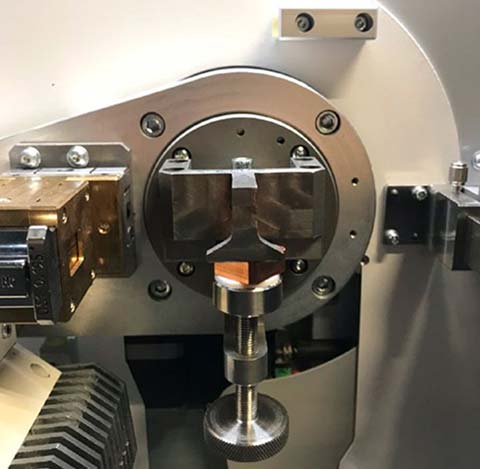

Variable-radius Ө–Ө goniometer

Precision scan geometry with radius range of 150–310 mm for symmetric and asymmetric high-resolution measurements.

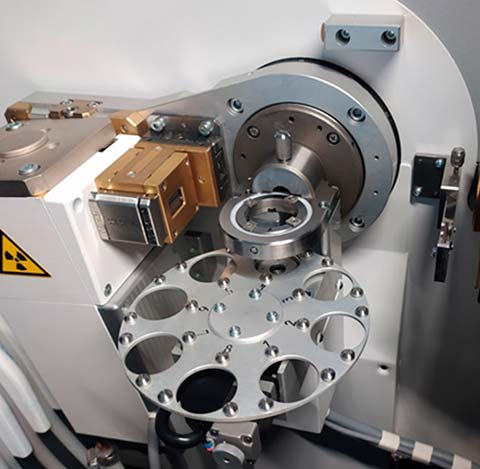

Photon-counting detectors

Multiple detector formats (0D, 1D, 2D) ensure optimal data collection for high-sensitivity and angular resolution experiments.

Ultra-high angular resolution

Achieves FWHM values down to 0.01°, ideal for epitaxial thin films, strain evaluation, and advanced crystallography.

High-power X-ray sources

Supports generators up to 60 kV / 50 mA (3000 W) for intense beam output and rapid data collection.

Modular high-resolution optics

Includes Goebel mirrors, parallel-plate collimators, and slits to match experimental needs from powder to epitaxy.

High mechanical and thermal stability

Ensures long-term reproducibility and data consistency in extended research and high-precision environments.

Video

Technical data

Details

| X-ray generator | 40 kV / 30 mA (1200 W) or 60 kV / 50 mA (3000 W) |

| Cooling system | Closed-circuit water cooling (internal or external) |

| Goniometer | Ө–Ө vertical, uncoupled, radius 150–310 mm |

| Scanning range | –12° to +160° (2Ө) |

| Minimal step | 0.0003° (2Ө) |

| Positioning accuracy | ±0.01° (2Ө) |

| Scanning speed | 0.01–600°/min |

| Detector types | 0D, 1D, 2D photon-counting Si detectors |

| Min. peak FWHM | ≤ 0.01° |

Peripherals

| Interface | USB / Ethernet |

| Computer | PC with Windows OS |

Dimensions

| Overall dimensions | |

|---|---|

| Width | 820 mm |

| Depth | 820 mm |

| Height | 1000 mm |

| Weight (maximum) | 130 kg |

|---|

Details

| X-ray generator | 40 kV / 30 mA (1200 W) or 60 kV / 50 mA (3000 W) |

| Cooling system | Closed-circuit water cooling (internal or external) |

| Goniometer | Ө–Ө vertical, uncoupled, radius 5.9–12.2 in |

| Scanning range | –12° to +160° (2Ө) |

| Minimal step | 0.0003° (2Ө) |

| Positioning accuracy | ±0.01° (2Ө) |

| Scanning speed | 0.01–600°/min |

| Detector types | 0D, 1D, 2D photon-counting Si detectors |

| Min. peak FWHM | ≤ 0.01° |

Peripherals

| Interface | USB / Ethernet |

| Computer | PC with Windows OS |

Dimensions

| Overall dimensions | |

|---|---|

| Width | 32.3 in |

| Depth | 32.3 in |

| Height | 39.4 in |

| Weight (maximum) | 287 lbs |

|---|

Related links

The fastest way to hear back from us is to fill the contact form below. Our appropriate department will get back to you depending on your inquiry as soon as possible.