Reinventing Waste Sorting with X-SORT: Physics, Intelligence, and Recycling

As global recycling targets become stricter and waste streams more complex, conventional sorting methods are showing their limits. Optical scanners fail in high-moisture environments. Mechanical separators struggle with composite materials. Manual labor remains expensive, inconsistent, and error-prone.

In response, AI-powered X-ray systems are emerging as a transformative force in waste management. Among these, X-SORT introduces a unique approach that combines dual-energy X-ray analysis, optical surface inspection, and adaptive neural processing — all in one platform.

Originally developed to extract glass from municipal solid waste (MSW), X-SORT is now being recognized as a universal sorting solution for diverse challenges: separating fire-resistant plastics, isolating ferrous and non-ferrous metals, recovering electronic fractions, and even enhancing compost purity. Its flexibility comes from the core technologies it integrates — and how they work together to solve real industrial problems.

The Problem: High-precision sorting of a wide range of materials at high speed

Waste today is no longer homogenous. Each stream may contain dozens of overlapping material types — from clear and colored glass to black plastics, metals, organic matter, and increasingly, composite or layered structures. Conventional optical and mechanical systems face major obstacles:

- Moisture and organic contamination obscure color-based detection

- Dark or flame-retardant polymers are indistinguishable by NIR sensors

- Stone and ceramics are misclassified as recyclable glass

- Non-ferrous metals are lost due to mass and density overlap

- E-waste contains embedded batteries and hybrid materials undetectable by surface imaging alone

The result? Lost recovery value, contaminated fractions, rejected batches, increased landfill — and an inability to meet tightening regulatory thresholds.

“It’s not just about separation anymore. It’s about recognition.”That insight, voiced by a European Commission waste strategy advisor, reflects the shift from mechanical handling to intelligent sorting. To meet recycling and purity targets, systems must understand the material they process — not just detect it.

A Sorting Landscape That Can’t Keep Up

Why AI and X-Rays Are Changing the Game

Dual-energy X-ray transmission (DEXRT) allows systems to evaluate material density and atomic composition — enabling separation by substance, not just appearance. When combined with neural networks trained on real-world samples, this gives rise to machines that can:

- Identify glass even when embedded in wet compost

- Sort dark-colored or multilayer plastics

- Differentiate aluminum from organic contamination

- Adapt to evolving materials through software updates

X-SORT builds on these foundations — adding real-time control, deep learning, and configurable ejection logic. The result is a system that doesn’t just scan. It learns. And it acts.

Inside the Technology: How X-SORT Works

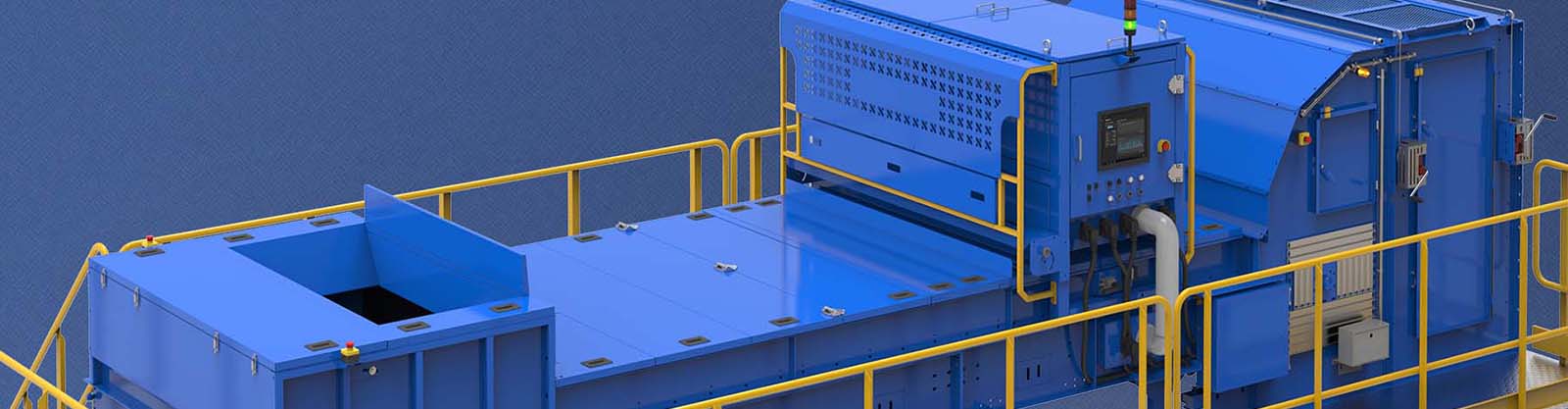

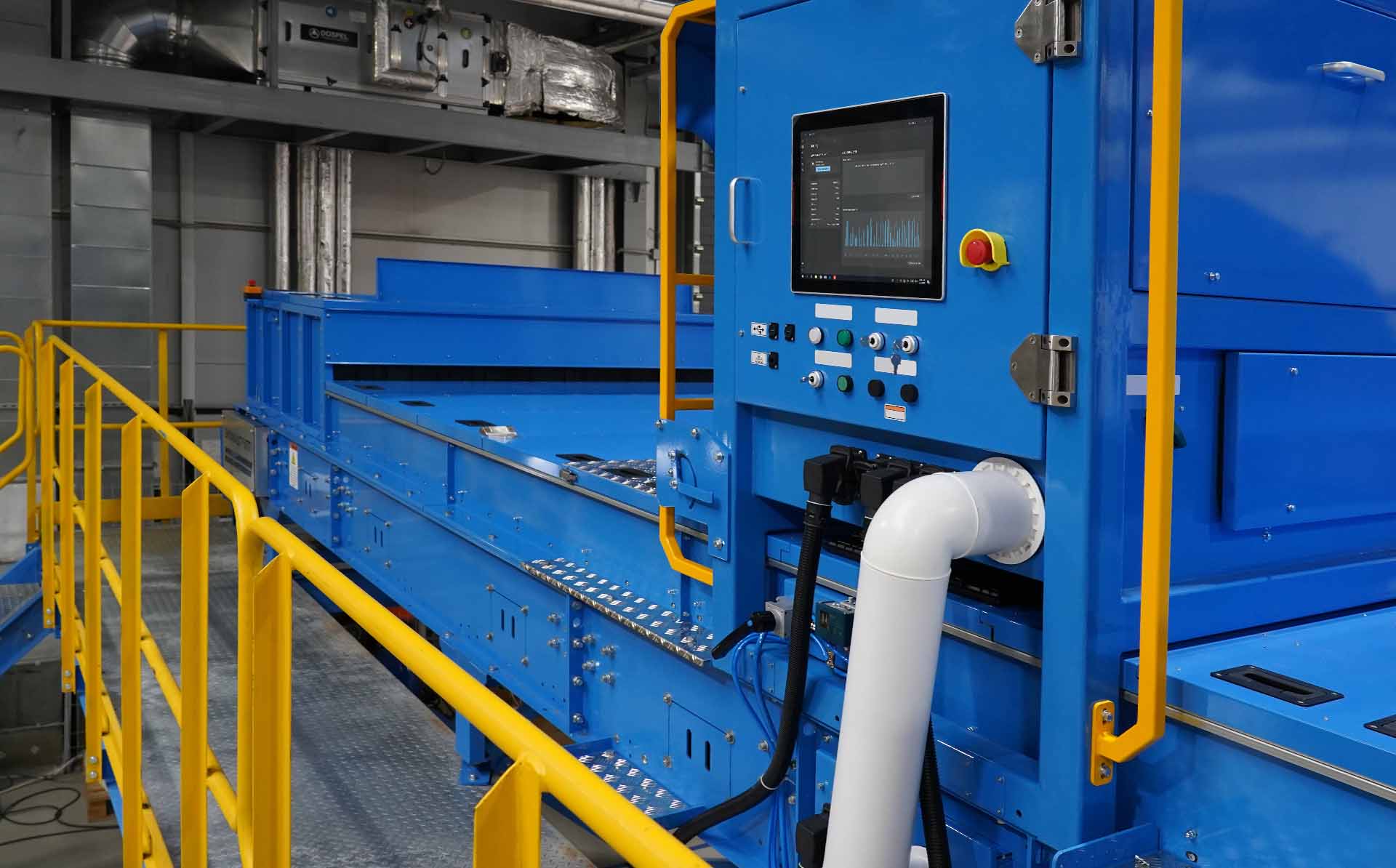

X-SORT is more than a machine — it’s a fusion of physical science and artificial intelligence. At the core of the system lies a synchronized detection pipeline that analyzes every waste fragment using complementary technologies:

- Dual-Energy X-Ray Transmission (DEXRT) – captures the density profile and effective atomic number (Zeff) of each item

- RGB Vision Module – detects surface color, shape, and texture

- Neural Inference Engine – interprets sensor data to classify materials by structure, not just appearance

Together, these components enable accurate identification of materials that would otherwise pass undetected — including glass covered in bio-waste, dark multilayer plastics, and lithium-containing electronics. Every item is evaluated in context, then sorted in real time using fast pneumatic ejection valves triggered with sub-5 ms delay.

The Three-Layer Sensing Architecture

Traditional waste sorters rely on either shape or surface cues. X-SORT adds a third dimension: chemical composition. Its three-layer architecture ensures robust classification:

| Sensing Layer | Function | Example Output |

|---|---|---|

| DEXRT | Measures X-ray absorption at high/low energy levels to determine density and atomic structure | Identifies ceramic vs. glass vs. plastic |

| RGB Camera | Analyzes visible features, texture, and form | Detects labels, reflective film, or surface defects |

| AI Engine | Fuses data into a material classification decision | Assigns “eject” or “pass” flag with category label |

The result is a sorter that understands — not just sees — the material passing beneath it. And it improves over time, as new data is incorporated into model retraining.

What Happens Inside the Tunnel?

The sorting process is fully autonomous once the material enters the system. A feeder spreads the incoming flow into a monolayer on a high-speed belt. Inside the shielded scanning tunnel, DEXRT and optical modules capture each object’s full signature.

What Happens Inside the Tunnel?

Within milliseconds, the neural engine determines the object’s class and center of mass. This map is used to activate a specific pneumatic valve that redirects the target to a collection bin — without disrupting the continuous flow.

The system operates without mechanical brushes or contact points in the detection zone, ensuring hygiene, low maintenance, and better uptime — especially when handling organic-rich waste.

“In glass-sorting trials, X-SORT achieved glass fragment over 85% detection efficiency with less than 5% contamination in the recovered fraction — outperforming optical-only systems.”– internal validation data, 2024

Real-World Applications: One Platform, Many Solutions

While X-SORT was initially designed for glass extraction, its architecture supports far more. The combination of dual-energy imaging and AI-based classification makes it highly effective in industries dealing with complex, contaminated, or overlapping waste streams. Below are examples where X-SORT delivers high-impact results.

| № | Application | Challenge | How X-SORT Solves It | Outcome / Benefit | Customizability |

|---|---|---|---|---|---|

| 1 | Glass in organic MSW | Small shards embedded in wet compost or food waste | DEXRT detects density even when glass is covered with moisture or dirt | High-purity cullet, reduced contamination, regulatory compliance | Retrainable AI for specific glass colors or composite types |

| 2 | Aluminum & copper in e-waste | Visual similarity to plastic or organics | X-ray signature recognizes metal content, regardless of color or coating | Improved non-ferrous metal recovery, less manual sorting | Adjustable threshold settings by density & fragment size |

| 3 | Dark or flame-retardant plastics | Undetectable by optical/NIR sensors | Material classification via density + optical fusion | Better plastic stream purity, downstream efficiency | Supports separation by plastic type (ABS, PVC, PET) |

| 4 | Organic fraction cleanup | Glass/plastic particles reduce compost grade | Real-time ejection of foreign materials from organics | Meets EU/US compost purity standards, protects soil | Adaptable to site-specific regulations |

| 5 | E-waste pre-sorting | Complex embedded structures, batteries, boards | Layered material recognition via AI + radiography | Higher recovery, safer handling, better final yields | Can flag specific items for manual disassembly |

“Versatility is built into the system. If your stream changes, you don’t need to buy new hardware. You retrain the AI.”– Lead systems engineer, AI Waste Research Initiative

Beyond the Machine: X-SORT as an Adaptive Platform

X-SORT is not a single-purpose machine. It’s a software-defined platform that evolves with your material streams, compliance needs, and business goals. Thanks to its modular logic layers and AI-based decision core, it delivers long-term flexibility with minimal hardware intervention.

AI Model Retraining

When new waste types or recovery targets emerge, the system’s neural models can be updated through supervised learning. Instead of changing sensors or mechanisms, the software adapts to recognize new patterns — enabling faster ROI and future-proof deployment.

Flexible Output Configuration

The pneumatic ejection system can be configured for 2-way, 3-way, or multi-stream sorting depending on your layout. Logic maps control which materials go where, and can be adjusted on demand without reengineering the system.

Seamless Line Integration

X-SORT can be integrated into existing MSW, MRF, or e-waste processing lines as a primary or secondary sorting stage. Its detection and separation logic operates independently, allowing processors to upgrade performance without overhauling infrastructure.

Data, Control, and Traceability

All classification decisions, object counts, and valve activations are logged in real time. Operators can access performance dashboards, adjust logic parameters, and export reports — supporting quality control, audit readiness, and regulatory reporting.

“AI-based X-ray sorters are one of the few technologies today that can improve both material recovery rates and compliance outcomes at once.”– European Environment Agency, Waste Technology Report 2023

X-SORT as an Adaptive Platform

X-SORT as an Adaptive Platform

Technical Overview at a Glance

X-SORT is engineered for continuous operation in demanding waste-handling environments. Below are the key operational parameters:

| Parameter | Specification |

|---|---|

| Throughput | Up to 20 tons/hour (44,000 lbs/hour) |

| Conveyor speed | Up to 3 m/s (9.84 ft/s) |

| Min detectable object | 10 × 10 mm, ≥ 2 mm height |

| Detection efficiency (glass) | ≥ 85% |

| Cross-contamination rate | ≤ 5% |

| Operational cycle | ≥ 20 hours/day |

| Power requirements | 3-phase, 400 V, 50/60 Hz, 22.5 kVA |

| Compressed air | 8 bar, ISO 8573-1:2010 Class 5:3:3 |

For detailed engineering drawings, data sheets, and system integration documentation, please visit the Technical Resources page.

Conclusion: A Smarter Path to Resource Recovery

Waste is no longer waste — it’s a resource stream. But to unlock its value, we need tools that understand complexity, learn from data, and adapt to change. X-SORT combines the physics of X-ray transmission with the intelligence of AI to do just that.

From municipal waste plants to electronics recycling centers, composting facilities, and industrial MRFs, X-SORT empowers operators to extract more value, meet tighter regulatory thresholds, and prepare for the evolving waste landscape of tomorrow.

Explore What X-SORT Can Do For You

Whether you’re looking to improve recovery from MSW, reduce contamination in your organics line, or explore customized material detection for your industry — X-SORT is ready.