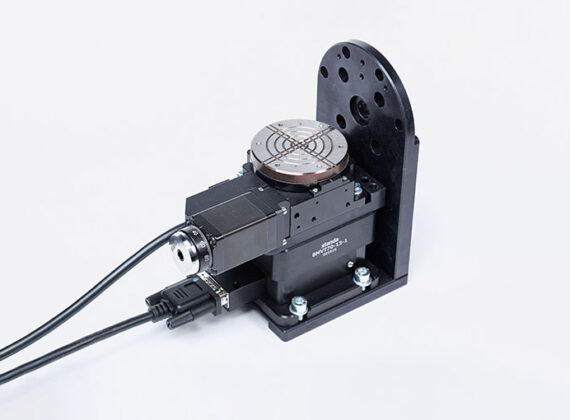

Description

The two-axis sample stage is an essential accessory designed to precisely align the

sample surface with the center of the primary X-ray beam in automatic mode, ensuring

optimal measurement accuracy and reproducibility.

This advanced stage is indispensable for a variety of specialized analytical techniques, including:

- Grazing Incidence X-ray Diffractometry (GIXRD): Perfect for thin-film analysis, allowing precise control of the incident angle to probe surface and interface structures.

- X-ray Reflectometry (XRR): Enables detailed characterization of thin films and multilayers by measuring reflectivity as a function of the incident angle.

- Sin² Residual Stress Determination: Facilitates accurate stress analysis in materials by aligning the sample at multiple angles for reliable stress calculations.

- Texture Measurement in Iso-Inclination Geometry: Ideal for studying crystallographic textures in polycrystalline materials, providing insights into material properties and processing effects.

- Determination of Crystal Orientation: Ensures precise alignment for determining the crystallographic orientation of single crystals, critical for materials research and quality control.

The stage features high-precision motors and intuitive software integration, allowing for seamless control and automation of complex alignment

procedures. Its robust design accommodates a wide range of sample sizes and shapes, making it a versatile tool for both routine and advanced

analytical applications. By enhancing measurement accuracy and reducing setup time, the two-axis sample stage significantly improves laboratory

efficiency and data quality.

Features:

- Maximum sample mass: 1 kg

- Maximum sample size: 70 mm (width) × 13 mm (height)

- Maximum Z-axis travel: 13 mm

- Minimum Z-axis travel: 0.625 μm

- Minimum rotation step in Phi angle: 0.002°

The fastest way to hear back from us is to fill the contact form below. Our appropriate department will get back to you depending on your inquiry as soon as possible.