Alanine is a simple amino acid (C₃H₇NO₂) commonly found in proteins. When exposed to ionizing radiation such as gamma rays, X-rays, or high-energy electron beams, alanine molecules form stable free radicals. A free radical is a molecule with an unpaired electron, which makes it highly reactive. Unlike many organic compounds where free radicals quickly recombine or degrade, the radiation-induced radicals in alanine remain stable for years under ambient conditions. These radicals can be detected and quantified using Electron Paramagnetic Resonance (EPR) spectroscopy. EPR, also called Electron Spin Resonance (ESR), is a spectroscopic technique that measures the magnetic properties of unpaired electrons. In simple terms, the EPR instrument applies a magnetic field and detects signals that correspond to the number and stability of free radicals. Because the radical concentration in irradiated alanine is directly proportional to the absorbed radiation dose, this method offers a precise way to measure dose levels.

The Dose Range Advantage: From Gy to kGy

Radiation dose is expressed in Gray (Gy), where 1 Gy equals the absorption of one joule of radiation energy per kilogram of material. In medical and industrial applications, the required doses vary dramatically:

-

Medical device sterilization: typically 15–25 kGy

-

Food irradiation for disinfection or shelf-life extension: 1–10 kGy

-

Polymer modification or cross-linking: 25–200 kGy

-

Research and radiobiology studies: as low as a few Gray

Alanine-EPR dosimetry provides a linear and energy-independent response over a vast range, from 1 Gy to 200 kGy. This universality eliminates the need for multiple dosimeter types and simplifies calibration procedures across different facilities and applications.

Radiation processing operates within tightly regulated frameworks. For example:

-

Medical applications must comply with ISO standards, FDA guidelines, and Good Manufacturing Practice (GMP) regulations.

-

Food irradiation is subject to strict limits to ensure consumer safety without altering nutritional properties.

-

Polymer research requires precise control of radiation dose to achieve desired mechanical or thermal characteristics.

An error of even a few percent in absorbed dose can mean incomplete sterilization, compromised safety, or wasted research outcomes. Alanine-EPR dosimetry provides accuracy with repeatability better than 1%, making it a regulatory-grade tool rather than a supplementary technique.

One of the defining strengths of alanine dosimetry is its energy independence. Unlike other dosimeters that show varying responses depending on the radiation source, alanine produces a consistent signal across gamma, electron beam, and X-ray irradiation. This makes it particularly valuable in facilities where multiple radiation modalities are employed.

In addition, alanine’s free radicals are remarkably insensitive to environmental influences such as humidity and moderate temperature variations. When combined with internal ruby references and autogain tuning within the spectrometer, the system achieves metrological accuracy under diverse laboratory and production conditions.

Comparing Alanine with Other Dosimetry Systems

Historically, several dosimetry systems have been used in industry and research:

-

Radiochromic films change color upon irradiation but can fade over time and are sensitive to environmental factors.

-

Thermoluminescent dosimeters (TLDs) require heating to release stored energy as light, a process that destroys the sample.

-

Fricke dosimeters, based on chemical solutions, are sensitive but prone to degradation and require immediate post-irradiation analysis.

In contrast, alanine-EPR dosimetry offers non-destructive, stable, and re-readable results. Once irradiated, the alanine pellets can be archived for years, re-measured if necessary, and used for retrospective validation-a critical feature for audit trails and regulatory compliance.

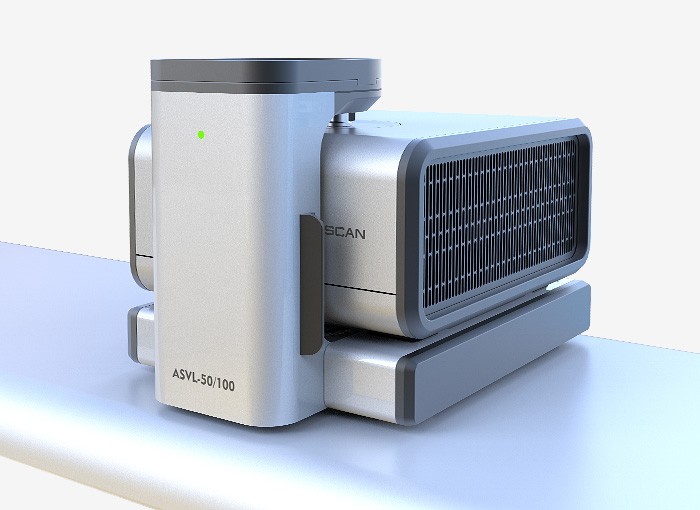

Modern alanine dosimetry systems, such as the LINEV Systems Alanine Dosimeter, are built around the SPINSCAN EPR spectrometer. This benchtop instrument provides high-resolution analysis of irradiated α-alanine pellets. Depending on user needs, the system can operate in:

-

Automated Mode – equipped with a 50- or 100-position autosampler, ideal for high-throughput industrial QA campaigns.

-

Manual Mode – compact and cost-effective, designed for research or low-volume applications, with the flexibility to upgrade later.

This modular architecture ensures scalability: laboratories can begin with manual setups and expand to automated workflows as demand increases.

A key advantage of contemporary alanine dosimetry systems is not only the spectrometer hardware but also the integrated software platform. The software performs several crucial tasks:

-

Calibration curve management: Establishes precise correlations between EPR signal intensity and absorbed dose using certified references.

-

Automated workflows: Guides operators through standardized operating procedures (SOPs) to minimize human error.

-

Batch processing: Enables simultaneous evaluation of dozens of pellets, reducing operator workload.

-

Data traceability: Maintains audit-ready archives with timestamps, operator IDs, and measurement logs.

By embedding these features, the software ensures that every measurement meets ISO/ASTM 51607:2013 standards, the globally recognized guideline for alanine-EPR dosimetry.

LV Analytical Alanine-EPR dosimetry system

Applications Across Industry and Science

Alanine-EPR dosimetry finds use in a broad spectrum of applications:

-

Medical device sterilization: Ensures every production batch meets safety requirements.

-

Pharmaceutical and cosmetic products: Provides reliable dose monitoring for sterilization without chemical residues.

-

Food irradiation: Maintains consumer safety and compliance with international trade regulations.

-

Polymer modification: Controls cross-linking and material properties for advanced engineering applications.

-

Medical physics research: Enables precise dose mapping for beam quality assurance and radiobiological experiments.

This versatility makes alanine dosimetry not just a specialized tool but a universal platform for radiation dose verification.

Because the alanine signal is non-fading and re-readable, irradiated samples can be archived for years. This capability is particularly valuable in regulated environments, where retrospective validation may be required during audits or legal inquiries. Unlike chemical or film-based dosimeters that degrade or lose signal, alanine maintains metrological fidelity indefinitely.

Meeting Regulatory and Operational Needs

With its energy-independent linear response, non-destructive readout, and compliance with ISO/ASTM 51607:2013, the alanine dosimeter stands as a gold standard for high-dose radiation metrology. As industrial processes demand ever greater precision and regulatory scrutiny intensifies, alanine-based systems will continue to provide the traceable confidence that science and society require.

Every aspect of the modern alanine dosimetry system has been engineered for compliance and usability:

-

Compact benchtop design integrates into both laboratories and industrial floors.

-

Minimal maintenance eliminates the need for chemical processing or daily recalibration.

-

Step-by-step workflows allow routine operation by technicians without specialized EPR training.

-

Scalability ensures suitability for single-unit labs or multi-line production environments.

By combining hardware stability, automated software, and regulatory alignment, alanine dosimetry offers a complete solution for both quality assurance and research innovation.