16 December 2025

How Multi-Energy X-Ray Arrays (MEA) and AI Are Redefining Cargo and Vehicle Inspection

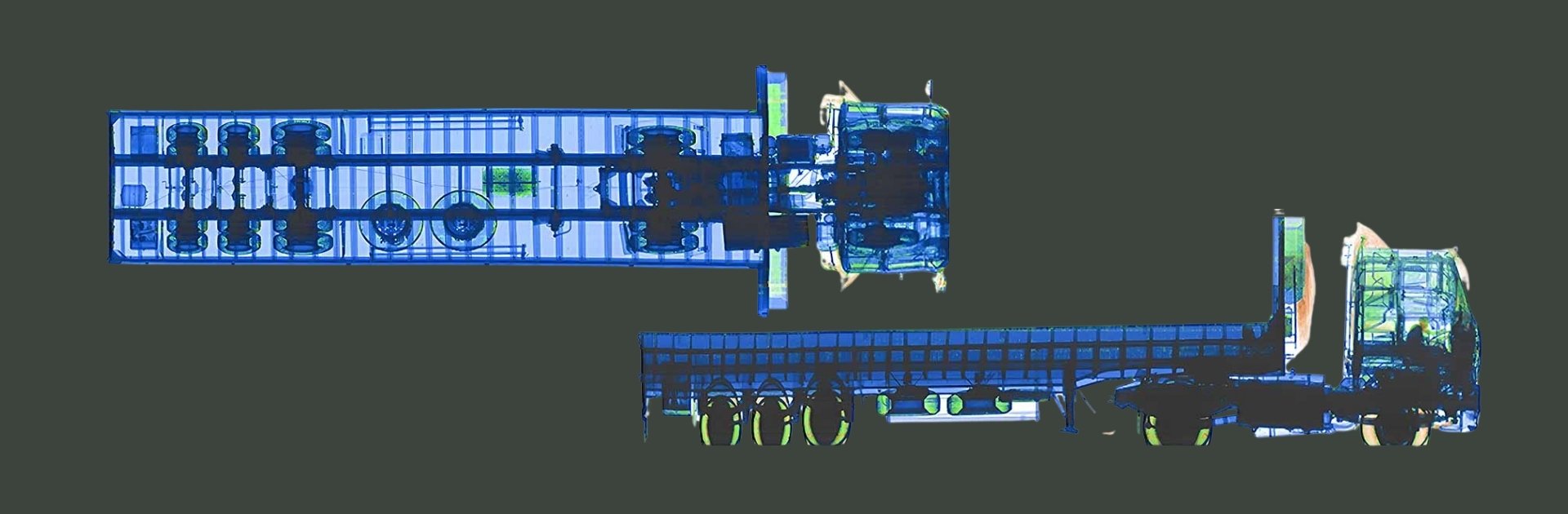

At LINEV Systems®, we’ve spent decades pushing the limits of X-ray imaging. Today, cargo and vehicle security is experiencing a remarkable upgrade due to AI and new detector technologies. At its center lies our Multi-Energy X-ray Array (MEA) technology, driving our MEAP and MEAP Spectral cargo & vehicle X-ray scanner.

Customs agencies, border crossings, ports, and critical infrastructure face an immediate challenge: screen cargo & vehicles more efficiently with better precision & speed. Single-energy systems no longer have the capability to do this. That’s why MEA and our AI stack were developed together as one integrated cargo and vehicle X-ray scanner ecosystem able to adapt to future needs.

Trade volumes continue to soar while security threats, from weapons and explosives to contraband goods, become increasingly sophisticated. Checkpoints must respond accordingly by equipping themselves with cargo & vehicle X-ray scanners capable of deeper material penetration, higher image quality and AI decision-making without impacting throughput.

MEA was developed to bridge the disparity between old technology and the new security environment.

Each MEA pixel in its detector has the capacity to distinguish among various energy levels of radiation passing through. It can detect how different materials absorb radiation across multiple energies, information crucial for accurate material classification.

MEA-based cargo and vehicle X-ray scanners, such as MEAP or MEAP Spectral, offer many advantages:

MEAP was developed to address three core problems of security operations: speed, accuracy, and adaptability.

First is speed: checkpoints cannot afford bottlenecks. MEAP can enable continuous drive-through inspection, enabling large volumes of traffic to pass quickly through with minimum disruption or need for manual stopping or repositioning of vehicles and containers.

Second is accuracy: MEAP can reveal subtle details and material differences missed by conventional cargo and vehicle X-ray scanners, combined with AI-powered assistance software to assist operators in quickly identifying suspicious areas, material composition and determining when secondary inspection is needed.

Third is adaptability: threats, regulations and smuggling tactics continue to evolve. MEAP was built as an adaptable platform that can accommodate changing requirements with software upgrades, AI models and integration with risk engines or customs databases.

Instead of a single projection, MEAP Spectral captures multiple views and uses them to construct a three-dimensional, spectrally rich representation of the inspected load. For operators, that means the ability to “look around” dense objects, reveal hidden cavities, and understand the spatial relationship between items inside a container or vehicle.

For high-risk cargo and high-value targets, this capability is critical. Smugglers are always coming up with creative ways of hiding contraband inside machinery, structural elements, or dense materials. A conventional cargo & vehicle X-ray scanner may provide enough information to suspect something is wrong, but not enough detail to localize the threat quickly. MEAP Spectral addresses this gap with:

Our AI models are trained to recognize patterns, materials, and threat signatures across the multi-energy data captured by MEA. They can flag anomalies, highlight suspicious regions, and provide automated “second opinions” that help inspectors focus their attention where it matters most.

Because MEA delivers a richer data stream than legacy systems, our AI has more information to work with. This leads to:

At LINEV Systems®, we designed MEAP and MEAP Spectral to be the cornerstone of a modern cargo & vehicle X-ray scanner ecosystem. They integrate with our assistance and threat detection software, connect to broader security architectures, and benefit from our continuous innovation in MEA, AI, and imaging.

Whether you are securing a national border, a major port, a logistics hub, or a critical infrastructure facility, our goal is simple: to help you see what others miss, at the speed your operations demand.

Customs agencies, border crossings, ports, and critical infrastructure face an immediate challenge: screen cargo & vehicles more efficiently with better precision & speed. Single-energy systems no longer have the capability to do this. That’s why MEA and our AI stack were developed together as one integrated cargo and vehicle X-ray scanner ecosystem able to adapt to future needs.

Why Traditional Cargo & Vehicle X-Ray Inspection Is No Longer Enough

Conventional X-ray inspection systems for cargo and vehicles typically utilize either single- or dual-energy imaging to gather information about object density and shape. However, they struggle with complex loads with concealment techniques. The fact that operators must manually interpret images under pressure means that threats may slip through among dense cargo loads, which require manual inspection to detect small hidden threats.Trade volumes continue to soar while security threats, from weapons and explosives to contraband goods, become increasingly sophisticated. Checkpoints must respond accordingly by equipping themselves with cargo & vehicle X-ray scanners capable of deeper material penetration, higher image quality and AI decision-making without impacting throughput.

MEA was developed to bridge the disparity between old technology and the new security environment.

Multi-Energy X-Ray Array Technology: The New Foundation

Our Multi-Energy X-ray Array (MEA) technology goes far beyond an upgrade; it represents an entirely different way of collecting and processing X-ray data. Instead of relying on limited energy bands to gather X-ray images, MEA utilizes an elaborate multi-energy detector array for more comprehensive spectral profiling of cargo being inspected.Each MEA pixel in its detector has the capacity to distinguish among various energy levels of radiation passing through. It can detect how different materials absorb radiation across multiple energies, information crucial for accurate material classification.

MEA-based cargo and vehicle X-ray scanners, such as MEAP or MEAP Spectral, offer many advantages:

- Enhance material discrimination to more clearly distinguish organics, inorganics, metals, and complex composites.

- Create greater contrast in areas where items would typically overlap and obscure one another.

- A more robust data foundation for automated threat detection algorithms.

MEAP: AI-Powered Multi-Energy Portal for High-Throughput Operations

Our Multi Energy X-ray Portal (MEAP) was developed as an intelligent cargo & vehicle X-ray scanner to meet requirements in high-volume border crossings, ports, logistics hubs and critical infrastructure environments. Equipped with MEA technology, MEAP delivers real-time high-resolution multi-energy images as vehicles or containers pass through its portal.MEAP was developed to address three core problems of security operations: speed, accuracy, and adaptability.

First is speed: checkpoints cannot afford bottlenecks. MEAP can enable continuous drive-through inspection, enabling large volumes of traffic to pass quickly through with minimum disruption or need for manual stopping or repositioning of vehicles and containers.

Second is accuracy: MEAP can reveal subtle details and material differences missed by conventional cargo and vehicle X-ray scanners, combined with AI-powered assistance software to assist operators in quickly identifying suspicious areas, material composition and determining when secondary inspection is needed.

Third is adaptability: threats, regulations and smuggling tactics continue to evolve. MEAP was built as an adaptable platform that can accommodate changing requirements with software upgrades, AI models and integration with risk engines or customs databases.

MEAP Spectral: Taking Cargo & Vehicle X-Ray to 3D and Spectral Tomography

While MEAP delivers advanced 2D multi-energy imaging, MEAP Spectral goes a step further by combining MEA technology with spectral tomography and 3D reconstruction. This transforms the way security teams see inside cargo and vehicles.Instead of a single projection, MEAP Spectral captures multiple views and uses them to construct a three-dimensional, spectrally rich representation of the inspected load. For operators, that means the ability to “look around” dense objects, reveal hidden cavities, and understand the spatial relationship between items inside a container or vehicle.

For high-risk cargo and high-value targets, this capability is critical. Smugglers are always coming up with creative ways of hiding contraband inside machinery, structural elements, or dense materials. A conventional cargo & vehicle X-ray scanner may provide enough information to suspect something is wrong, but not enough detail to localize the threat quickly. MEAP Spectral addresses this gap with:

- 3D localization of suspicious objects within complex cargo layouts.

- Spectral data that improves the classification of materials in three dimensions.

- More intuitive visualization for operators, reducing cognitive load and training time.

AI as a Tool for Human Operators

At LINEV Systems®, we do not view AI as a replacement for human expertise. Instead, it is a tool that turns a cargo & vehicle X-ray scanner into a collaborative partner for the operator.Our AI models are trained to recognize patterns, materials, and threat signatures across the multi-energy data captured by MEA. They can flag anomalies, highlight suspicious regions, and provide automated “second opinions” that help inspectors focus their attention where it matters most.

Because MEA delivers a richer data stream than legacy systems, our AI has more information to work with. This leads to:

- Reduced false alarms, because material signatures are more precisely understood.

- Faster decision-making, as suspicious regions are automatically highlighted.

- Consistency across shifts and locations, even when experience levels vary.

Building a Future-Ready Cargo & Vehicle Inspection Ecosystem

Cargo and vehicle inspection is evolving. Regulatory expectations are increasing, supply chains are under strain, and threats are adapting. Security leaders need systems that not only meet today’s requirements but also evolve with tomorrow’s challenges.At LINEV Systems®, we designed MEAP and MEAP Spectral to be the cornerstone of a modern cargo & vehicle X-ray scanner ecosystem. They integrate with our assistance and threat detection software, connect to broader security architectures, and benefit from our continuous innovation in MEA, AI, and imaging.

Whether you are securing a national border, a major port, a logistics hub, or a critical infrastructure facility, our goal is simple: to help you see what others miss, at the speed your operations demand.